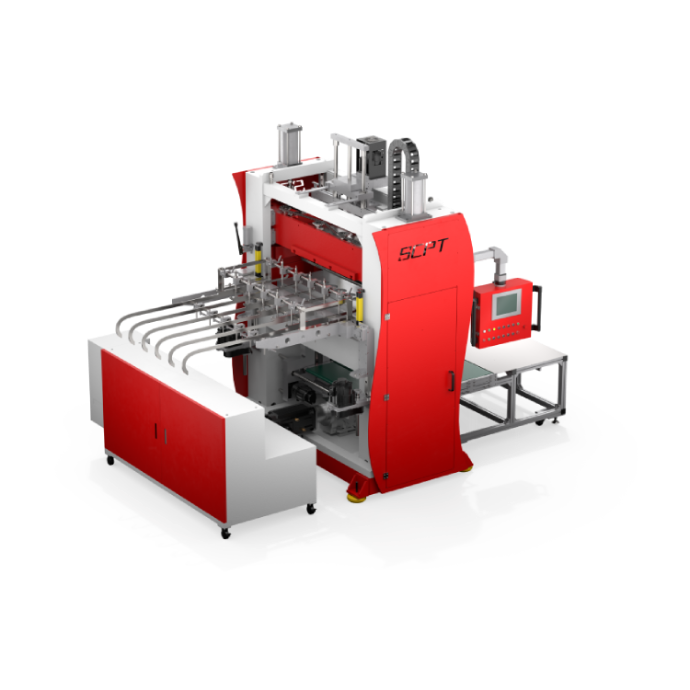

Thermoforming Production Line

Model No: TF-1012+ SC-1042 Thermoforming Production Line

Thermoforming Machine (TF-1012)

The TF-1012 utilizes low-temperature control to achieve flawless forming quality with user-friendly operation. Smart Absolute Value Servo Motor Control enables faster positioning and ensures a stable machine body without any shaking.

Shape Cutting Machine (SC-1042)

The SC-1042 is designed for processing finished product shapes, featuring a robust steel plate welded structure that undergoes annealing treatment to minimize deformation ensuring excellent parallelism of the upper and lower die beds.

Equipped with servo motors and linear guides, the machine operates smoothly.

The use of special steel cutting tools ensures smooth and burr-free trimming cuts.

Feature

- Material Transfer System

Automated material loading for efficient and rapid loading, capable of completing the process within 2 minutes. - Human-Machine Interface System

Product parameters are digilized and can be stored, facilitating easy management and application. - Tunnel-Type Heating Oven

The oven features separate upper and lower heating zones, allowing independent adjustment and localized temperature control, providing high flexibility.

With a three-stage heating process, it ensures smoother and ripple-free forming, especially for special materials.

Suitable Materials

PS, PP, OPS, PET, HIPS, ABS, PVC