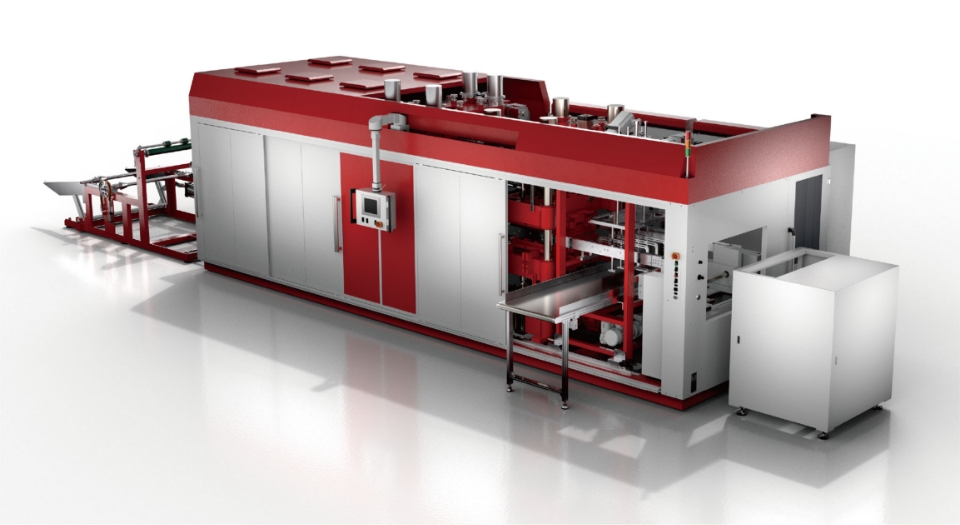

Plastic lunch box production solutions(Option 1)-Thermoforming + Cutting + Stacking = One Smart Line

(Small batches of diverse products)

SCPT Machinery-featuring advanced technology and high flexibility, provides a comprehensive solution for the production of small batches of diverse plastic food containers. It significantly enhances production efficiency, reduces energy consumption, and meets the demands for automation and intelligent manufacturing.

The machine’s low-temperature forming technology uses powerful vacuum force to achieve precise forming at lower temperatures, avoiding material deformation caused by traditional high-temperature forming. The intermediate cooling plate effectively cools the material, enhancing product quality and energy-saving performance, which in turn reduces operational costs.

The automation and smart design further increase production efficiency. Every step, from feeding, heating and forming, punching, cutting, to mechanism lubrication, is highly automated. The intelligent data collection system monitors production data in real-time, while the DAG cloud platform provides convenient and intelligent production management, helping businesses better control the production process, improve efficiency, and reduce reliance on human resources, thus meeting the demands of small-batch, diverse production.

The high-precision temperature control system independently controls the temperature of each zone, using SSR-configured PID algorithms for precise temperature compensation. The edge preheating system improves production yield and reduces the generation of defective products. It also features an automatic shutoff function for the electric heating based on material length, achieving energy savings of 35-40%. The high-precision temperature control system ensures the high quality of finished products while significantly reducing energy consumption, realizing both environmental and economic benefits.

Features and Characteristics:

Small Quantity, Diverse Production Capability

The demand for plastic food containers in the modern market is increasingly diverse. The need for containers of different shapes, sizes, colors, and materials varies, posing higher requirements for the flexibility of production equipment. SCPT Machinery-production line can complete the manufacturing of different batches of products in a short time without the need for cumbersome mold changes, significantly enhancing production flexibility and efficiency. This capability for small-scale, varied production allows businesses to quickly respond to market changes and meet the diverse needs of customers.

Quick Adjustment Production Line Design

Advanced CNC technology and intelligent control systems allow for rapid adjustment of production parameters, reducing production downtime, improving efficiency, and minimizing the risk of human error.

Integrated, Efficient Production Process

The thermoforming Production Line integrates multiple production steps, including forming, cutting, and stacking, all completed in one process. From feeding plastic sheets to discharging finished food containers, the entire process can be accomplished with a single machine. This integrated design not only simplifies the production process but also significantly reduces labor and equipment costs, enhancing production efficiency. Additionally, the highly automated equipment ensures that each step is executed with precision, improving the quality and consistency of the final products.

Precise Raw Material Conveying System

The automatic feeding and discharging system ensures a stable supply of raw materials, enhancing production efficiency and product consistency while reducing the labor intensity of operators.

Low-Temperature Controlled Forming Mechanism

The main structure of the Thermoforming Production Line adopts low-temperature control technology, allowing high-quality forming at lower temperatures and preventing damage to plastic materials from high heat. The machine is also equipped with a mold lifting mechanism, a design that not only reduces effort but also effectively saves energy, enhancing production cost-efficiency. The application of low-temperature control technology ensures the appearance quality and mechanical properties of the final products.

Advanced 3M heating furnace technology

The Thermoforming Production Line utilizes 3M heating furnace technology, equipped with upper and lower heating furnaces that are independently controlled by zones. This design allows the temperature in each zone to be adjusted according to actual needs, while the cooling device attached to the middle partition effectively prevents heat dissipation, further enhancing temperature control precision. This flexible and precise heating method ensures the optimal heating condition of plastic materials, thereby improving the quality of the final products.

Precise cutting machine and automatic stacking mechanism

The high-precision cutting machine ensures that the dimensions and appearance of the finished products meet design requirements, while the automatic stacking mechanism can be set to stack a specific number of products, improving production efficiency and facilitating packaging and transportation.

Flexible discharging mechanism design

The discharging mechanism can be configured for front or side discharge, adapting to different production sites and layout requirements, thus enhancing the equipment's adaptability and flexibility.

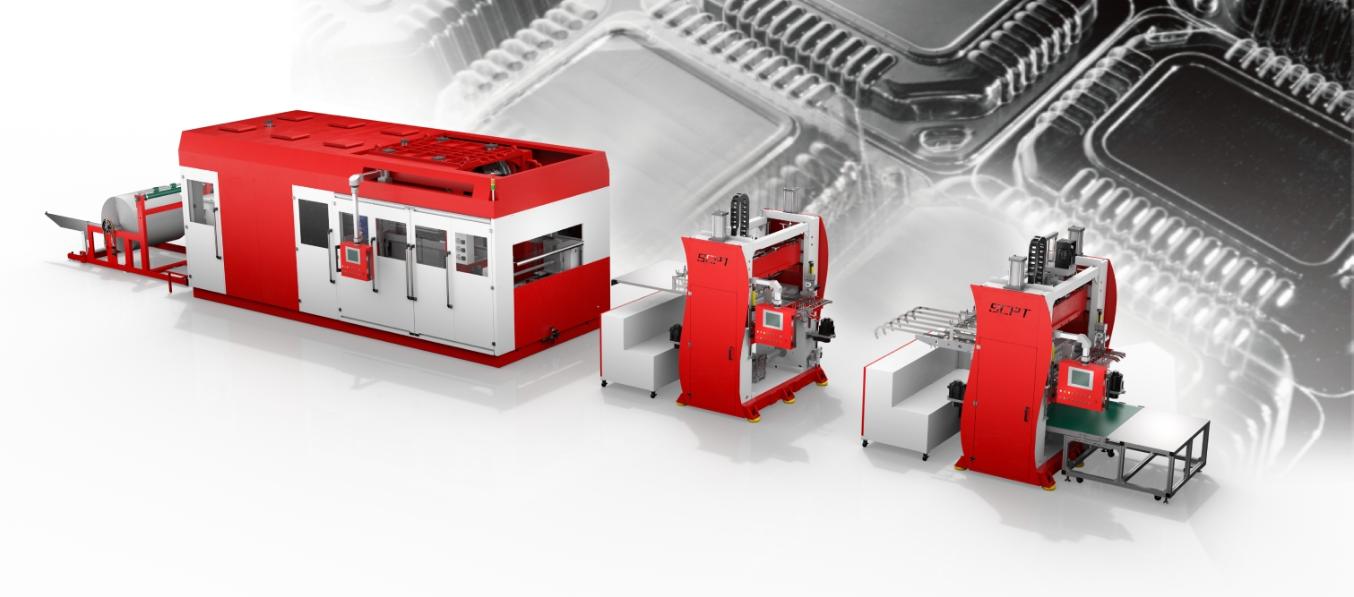

Plastic lunch box production solutions(Option 2)-Flexible Combination Thermoforming Solution: Thermoforming + Punching + Cutting + Stacking

(Meet Diverse Production Demands)

SCPT Machinery- Automatic Thermoforming Production Line not only achieves a leading level in technology but also significantly improves operational convenience and product quality. It provides various flexible, reliable, and efficient production solutions for different types of plastic food container production lines, making it an ideal choice for companies aiming to enhance productivity and competitiveness. By implementing this production line, companies can respond more flexibly to market demands, improve product quality, and reduce production costs, thereby standing out in the fierce market competition.

Features and Characteristics:

It is equipped with a raw material conveying system that allows for automatic feeding, making the process both labor-saving and quick, completing the feeding process within 2 minutes and significantly improving production efficiency. The human-machine interface system digitizes and stores product parameters, making management and application easier, thereby enhancing operational convenience and production efficiency.

In addition, the production line is equipped with a tunnel-type heating furnace, featuring an upper and lower heating furnace design with independently adjustable zones. This allows for localized temperature adjustments for different materials, offering high flexibility. The three-stage heating system is particularly beneficial for forming special materials, ensuring that the finished products are smoother and free of ripples. This feature is especially useful in the production of plastic food containers, ensuring stable quality and a good appearance for each container.

Provides a variety of flexible combination solutions

Option 1

TF-1012 Thermoforming machine + PH-1042 Punching machine+SC-1042 Shape Cutting machine ->Automatic Stacking.

This solution is suitable for companies that require high-efficiency and multi-step automated production.

Option 2

TF-1012 Thermoforming machine + SC-1042 Shape Cutting machine->Automatic Stacking.

Suitable for product production that does not require punching process.

Option 3

TF-1012 Thermoforming machine + Automatic Cutting and Stacking Mechanism + Hydraulic Cutting Machine + Manual Material Collection

This solution is suitable for situations where a more flexible production configuration is required

The applicable materials range is wide, including PS, ABS, PP, PET, PVC, OPS and HIPS and other materials. These materials have a wide range of demands in their respective application fields, and after being processed by this set of equipment, high-quality products can be achieved.