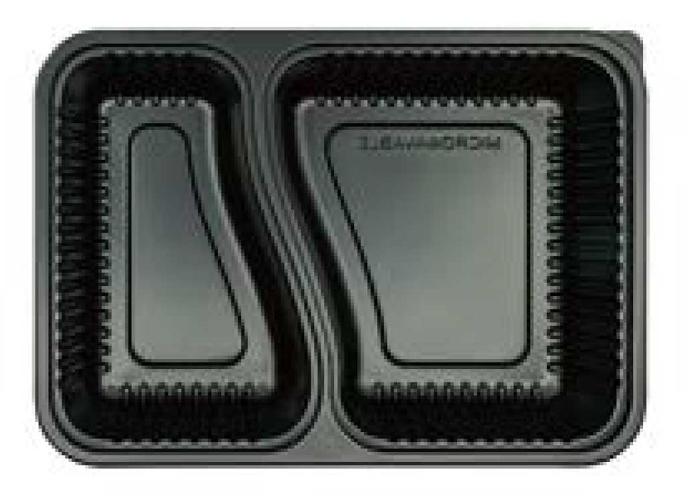

Suitable Materials

PS, PP, OPS, PET, HIPS, ABS, PVC

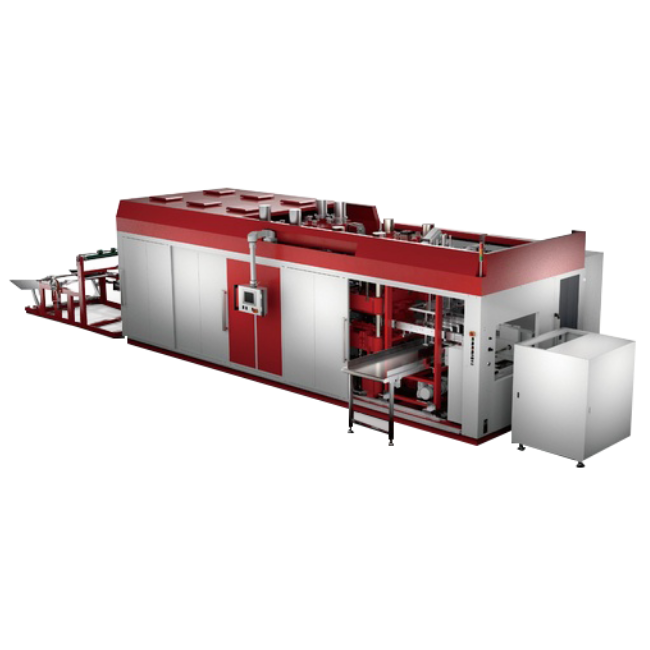

| SPECIFICATION | |

| Forming Area (mm) |

Max.800 | Min.600 |

| Film Thickness (mm) | 0.2 - 1.8 |

| Film Width (mm) | Max.810 | Min.600 |

| Mold Height (mm) | 200-400 (upper mold plus bottom mold) |

| Clamping Force (ton) | 42 |

| Molding Type | Pressure Forming and Vacuum Forming |

| Operation System | Automatic human-machine touch screen interface |

| Machine Size (mm) | W13950 | D 4020 | H 3120 |

| Machine Weight (ton) | 22 TON | Power 70 HP |